Causes & Improvements

Bearing lubricant volatilization

Lubricant vaporizes with long-term use in high temperature

Lubrication effect degradation

Bearing abrasion

Continuous abrasion of bearing ball due to lubrication effect degradation

Exposure to thermal expansion pressure due to spindle tolerance trouble

Increasing ohmic loss of motor

Increase of mechanical loads due to bearing abrasion

Increasing electric ohmic loss of motor

Thermal fuse disconnection due to heating

Excessive current flow to the coil

Excessive current converted to heat

Cooling fan melt down

Fuse disconnection due to excessive heat generation

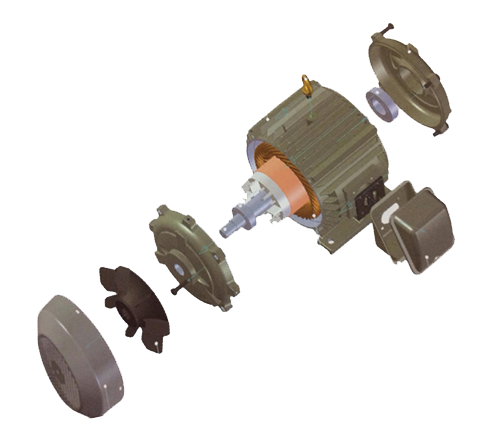

Rotor shaft fit

5/100 => 2/100mm tolerance processing

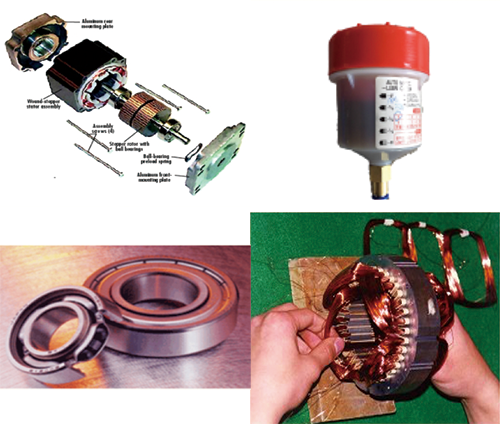

Long lasting bearing

Adopting the correct volume bearing (6208)

Stainless balls, 150℃ type grease

Automatic lubricator mounted

Grease injection and recovery device for high temperature is mounted

Supply 5.2cc monthly and replace cartridge once a year

Heat resistance treatment for stator coil

Stator coil heat resistance treatment suitable for hot condition

High temperature insulation

Improvements

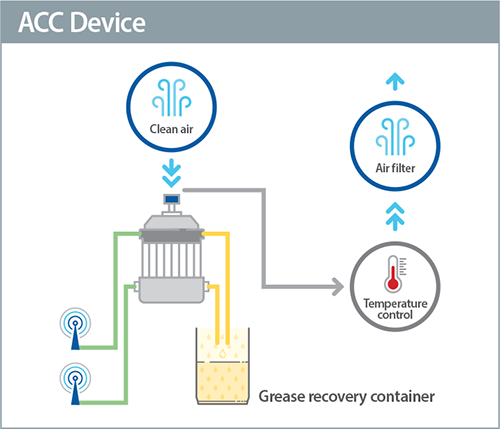

Grease injection line by refurbishing the shaft of upper and lower bearing position

Stable operating state that flow path of clean air and cooling air is separated and secured

Automatic grease injection

Automatically inject 0.17cc daily

Automatic grease painting

Automatic painting due to rotation of ball

Extra grease is discharged by centrifugal force